Gaskets and seals are a key component of cars, motorcycles and quad bikes to help prevent oils, coolants, and other lubricants from entering the engine and compromising the vehicle’s performance. They are used throughout the engine’s mechanics, such as on the Exhaust Gas Recirculation (EGR) valves to help reduce harmful nitrogen oxide emissions and to prevent leakage from the camshaft and rocker covers.

Over the last 50 years, we have manufactured large runs of automotive gaskets for some of the world’s most recognisable vehicle manufacturers. From our factory in West Yorkshire, our skilled team use a wide range of metal, graphite, rubber, cork, nitrile, non-asbestos and composite sheet materials to mass-produce gaskets and seals for a wide range of vehicle makes and models.

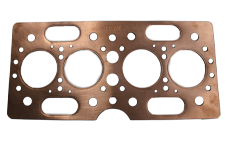

We manufacture cylinder head, exhaust, sump and manifold gaskets for a wide range of classic cars and motorbikes.

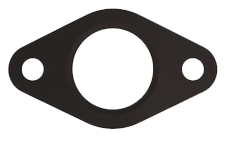

Used to seal the camshaft, these O-Ring gaskets are typically smaller than manifold and cylinder head gaskets. Some automotive engines feature one camshaft, whereas others require several camshaft gaskets.

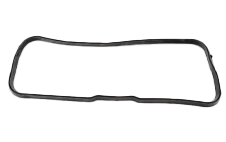

An essential seal to prevent oil leakage between the rocker cover and engine, these gaskets can be manufactured from a range of cork, nitrile and non-asbestos materials.

Manufactured from flexible graphite or composite materials, EGR and automotive valve gaskets have excellent resistance to high temperatures, oils and fuels.

Whatever the make, model, or age of your vehicle, our experienced team can swiftly manufacture large quantities of bespoke gaskets using customers’ CAD drawings, specifications and existing parts.

All gaskets are produced in-house utilising the latest laser, water jet and punch press machinery, before being hand-finished using a range of modern and time-served techniques. Our gaskets can be supplied worldwide and have been produced in accordance with all recognised national and international standards.

We precision-manufacture large runs of automotive gaskets quickly and efficiently to suit customer requirements in any thickness, shape or size. Our vastly experienced team are also on hand to advise the best type of gaskets for your vehicle.

| Material | Application | Temp range | Max PSI/BAR |

| Graphite | Manifold / Head Gaskets / EGR | Min -100 Max 500 °C | 250 BAR |

| Non-Asbestos | Manifold / Head Gaskets / Shims / Rocker Cover | Min -50 Max 450 °C | 100 BAR |

| Metal | Manifold / Head Gaskets / Shims / Camshaft | Min -250 Max 550 °C | 250 BAR |

| Various Rubbers & Cork | Rocker Cover / Sump | Min -20 Max 90 °C | 10 BAR |

| Various Composites | |||

| High Temp | EGR | Max 1100 °C | N/A |

| Sponge & Foam | Light Cluster Seals | Min -20 Max 100 °C | 10 BAR |

Our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide range of gasket applications.

Our gaskets are manufactured to fit a wide range of modern and classic cars, motorcycles and quadbikes of any make and model. Alongside producing a range of automotive gaskets and seals for Land Rover, we have worked alongside a number of clients in the agricultural sector to produce gaskets for heavy-duty machines.

We supply a vast range of gasket materials, available to buy directly or order from us. For more information visit the Gasket Sheet Materials page