Plastic gaskets are commonly used as an alternative to metal and demonstrate good durability and corrosion resistance. Gaskets of this type are typically lightweight and low friction with good sealing and insulation properties.

We hold a large stock of plastic shim and gasket sheet materials in a wide range of thicknesses and can source, supply and convert sheets to suit the application.

Nylon packer and spacers gaskets can be cut to any shape to widths of 10mm from a range of sheet materials, such as Nylatron, using die-cut, laser and water-jet machinery.

Low density (LDPE) and high density (HDPE) are polyethylene plastics with properties of minimal moisture absorption, resistance to chemicals and good strength.

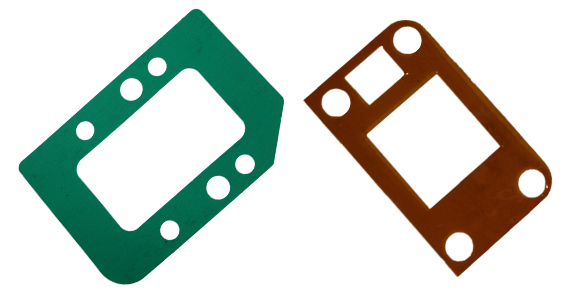

We convert colour-coded plastic shim gaskets from a range of sheet materials including nylon, vinyl, acetate, polypropylene and polyethylene.

Polycarbonate has excellent impact, durability, heat and flame resistance properties. This thermoplastic provides high levels of mechanical, optical and electrical properties.

We convert plastic sheeting for short and long runs of standard and bespoke plastic gaskets. The width of the sheet dictates the method of conversion, with our water jet and CNC cutting machines able to cut almost any depth of plastic with precision and consistency across the run. We stock a wide range of plastic gasket sheet materials. Cut up to 200mm on water jet

Client utilise our full turnkey gasket manufacturing service for help with materials specification and prototyping, along with CAD gasket design, bespoke manufacture and worldwide distribution. All gaskets are supplied to recognised national and international standards.

Plastics are, in general, a low-cost and versatile material for manufacture gaskets Plastic compounds exhibit a broad range of properties and applications from simple colour coded plastic shim gaskets to corrosion resistance gaskets used in critical operations. We supply a comprehensive range of shim material, nylon sheet and specialist plastic composites that can be converted by die-cutting. If you would like more information about specific plastic materials and conversions, please don’t hesitate to contact our technical team.

| Materials | Temperature Range | Max PSI/BAR | PN Range | Download |

| ABSAcetal (Delrin®) | 75 °C | 150 | 2.5/320 | |

| AcetateMylar® Polyester | 130 °C | 150 | 2.5/320 | |

| FilmTeflon® (PTFE)Nylon Low | 260 °C | 150 | 2.5/320 | |

| Density Polyethylene (LDPE) High | 80 °C | 150 | 2.5/320 | LDPE datasheet |

| Density Polyethylene (HDPE) High Impact | 80 °C | 150 | 2.5/320 | |

| Polymide Film | 110 °C | 150 | 2.5/320 | |

| Polycarbonate (Lexan®) | 120 °C | 150 | 2.5/320 | |

| Plastic Shim Stock (Colour Coded) | 130 °C | 150 | 2.5/320 | Colour-Coded datasheet |

| Polypropylene | 100 °C | 150 | 2.5/320 | |

| Polyethylene (UHMW) | 80 °C | 150 | 2.5/320 |

Our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide range of gasket applications.

Thermoplastics and thermosetting polymers have been used sealing applications for decades due to inherent advantages over other materials. In part this is due to the low material and production costs but also its relative resistance to elements such as heat, climate, fire, oil, hydrocarbons and chemicals.

Industries such as Aerospace increasingly use plastic gaskets as an alternative to metal. In critical applications where the strictest standards must be adhered to, its excellent wear resistance and high strength to weight ratio make it a viable and cost-effective sealing material.

We supply a vast range of gasket materials, available to buy directly or order from us. For more information visit the Gasket Sheet Materials page