PTFE materials, or Polytetrafluoroethylene materials, are made of synthetic fluoropolymer of tetrafluoroethylene. Most commonly known by the trademark name Teflon®, the inert nature of the material means it is highly hydrophobic, have one of the lowest coefficients of friction and is resistant to most chemicals. PTFE gaskets can be reinforced with fillers such as carbon or graphite to reduce creep under high pressures and temperatures.

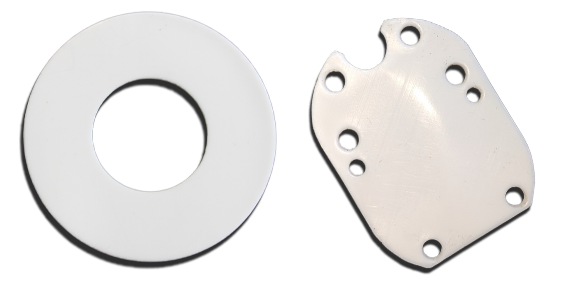

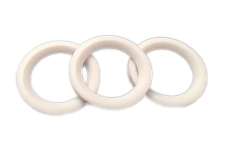

We precision cut virgin and composite PTFE gasket profiles to suit a wide variety of sealing applications.

Has excellent chemical and electrical resistance properties with a low coefficient of friction. Often used in food, water and pharmaceutical applications.

Adding glass and carbon in the PTFE sintering process adds mechanical strength to the material and reducing creep under higher pressures.

The non-stick characteristics of Teflon® (PTFE) mean that it requires chemical modification, or etching, in order to bond with other surfaces.

Virgin PTFE is expanded during manufacture, altering its structure to improve dielectric and recovery characteristics under low bolt load.

Our PTFE Teflon Gaskets and seals are cut to precise tolerances in small or large quantities utilising in-house CNC machinery to suit customer requirements. Our manufacturing process ensures that production is cost-effective, efficient and accurate.

Our turnkey gasket manufacturing solutions have been developed to help clients with materials specification and prototyping where required. This often includes CAD gasket design, standard and bespoke manufacture and distribution. All gaskets are supplied to recognised national and international standards.

PTFE materials can be altered under manufacture to suit various sealing applications, providing resistance to chemicals, temperatures and liquids. Virgin, expanded and filled PTFE are incredibly versatile materials that offer good recovery and stability under a wide range of temperatures and pressures. In processes involving chemicals, the material is largely non-corrosive and can be strengthened through the use of fillers such as carbon, glass, or specialist composites, such as metal detectable PTFE.

The improved compressibility characteristics of Expanded Virgin PTFE make it an obvious choice for use where connections have become damaged or worn. Virgin and expanded materials are supplied to meet MHRA and FDA standards.

| Materials | Temperature Range | PN Range |

| Virgin | -200°C up to +260°C | 2.5/320 |

| Blue Food Quality | -200°C up to +260°C | 2.5/320 |

| Expanded PTFE | -240°C up to +270°C | 2.5/320 |

| Carbon Filled | -200°C up to +260°C | 2.5/320 |

| Glass Filled | -260°C up to +250°C | 2.5/320 |

| Stainless Steel Filled | -200°C up to +260°C | 2.5/320 |

| Bronze Filled | -200°C up to +260°C | 2.5/320 |

| Metal Detectable | -200°C up to +260°C | 2.5/320 |

Our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide range of gasket applications.

Commonly used in pipework and flanges where chemicals are present, PTFE gaskets have an extremely low coefficient of friction and good resistance to moisture and corrosion. The anti-stick properties of the material mean PTFE is commonly found in applications with parts that have linear or rotary movements.

Often used in food and pharmaceutical processes, we supply PTFE materials that meets international hygiene standards with traceable certification available where required.

We supply a vast range of gasket materials, available to buy directly or order from us. For more information visit the Gasket Sheet Materials page