When selecting a marine engine gasket, it is important to consider the International Maritime Organisation (IMO) guidelines, the direction of engine rotation, and whether the engine cooling system is open or closed in order to ensure a long-lasting seal. With requirements including resistance to high temperatures, fuels and oils, corrosion and weathering, our experienced team are on hand to advise the correct gasket for your engine.

Over the last 50 years, we have manufactured a variety of marine engine gaskets, from small boats to large aircraft carriers and submarines. All of our gaskets are fabricated in-house at our factory in West Yorkshire, with our skilled team using modern and time-served techniques to precision-cut gaskets from metal, rubber, composite and non-asbestos sheet materials to fit a wide range of machine engine makes and models.

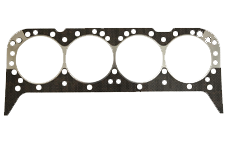

These gaskets are typically manufactured from composite materials, traditional metals such as copper or steel, or a combination of the two to offer excellent durability and thermal conductivity.

Due to their resistance to rust and corrosion, marine manifold gaskets are commonly fabricated from metals including copper and stainless steel, or non-asbestos fibres such as Klinger or Novus.

Valve and Rocker Cover gaskets create a tight seal between the engine cover and engine and are typically fabricated from plastic, rubber, or cork sheet materials highly resistant to fluctuating temperatures, oils, and fuels.

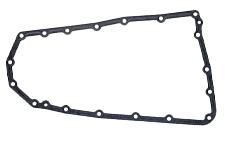

Replacing an oil pan gasket often requires the complete removal of the engine. Corrosion and fuel-resistant materials such as stainless steel and rubber composites ensure that oils and fuels remain contained to prevent leakage.

All our marine engine gaskets are manufactured in-house using the latest laser, water jet and punch press machinery, before being hand-finished using a range of modern and traditional processes. Whether producing one-off gaskets or large runs, we ensure the same high-quality craftsmanship to every gasket and seal that leaves our factory.

We offer a full turnkey service, including advising clients on the correct sheet material for their application, CAD and design specifications, bespoke manufacture, and worldwide shipping. All of the marine engine gaskets supplied to our clients are in accordance with IMO, national and international regulations.

We stock a wide range of gasket sheet materials suitable for use in the marine industry, which can be precision-cut to any shape, size and thickness to meet client requirements.

Due to their excellent resistance to high temperatures, corrosion, oils, and fuels, metal, rubber and composite sheet materials are typically favoured, with our experienced team on hand to advise the correct material for your application.

| Material | Application | Temp range | Max PSI/BAR |

| EPDM | Engine / Head/ Oil Pan Gaskets | Min -30 Max 100 °C | 10 BAR |

| Non-Asbestos | Manifold / Head Gaskets | Min -50 Max 450 °C | 100 BAR |

| Metal | Engine/ Manifold / Head Gaskets | Min -250 Max 550 °C | 250 BAR |

| High-Temp | Valve Covers | Max 1100 °C | N/A |

| PTFE | Engine / Manifold / Oil Pan Gaskets | Min -260 Max 270°C | N/A |

| Cork | Engine / Valve Covers | Min -30 Max 100°C | N/A |

Our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide range of gasket applications.

Alongside manufacturing gaskets for a wide range of engine makes and models, we also supply gaskets and seals for a variety of other marine applications, including hatch covers, internal and external systems, and pipework repairs.

We supply a vast range of gasket materials, available to buy directly or order from us. For more information visit the Gasket Sheet Materials page