At Dobsons Gaskets, we specialise in the design and manufacture of high-quality rubber and silicone gaskets tailored to a wide range of applications. Our extensive stock includes both commercial and BS specification-grade sheet materials, ensuring a fast, reliable supply for standard requirements.

For more specialised projects, we can source and provide bespoke materials at highly competitive prices, delivering solutions that meet exacting performance and industry standards.

Choosing the right gasket material can be critical to the success and longevity of your project. To make this process easier, we’ve developed our downloadable Rubber Gasket Selection Guide, providing detailed information on material properties, performance characteristics, and recommended applications.

RELATED RUBBER PRODUCTS: Rubber Gaskets Overview | EPDM Rubber Gaskets | Neoprene Gaskets | Silicone Gaskets | Hypalon Gaskets | SBR Gaskets

A cost-effective and versatile sealing solution. SBR (styrene-butadiene rubber) is often used in applications where moderate temperature and pressure conditions are involved.

Most commonly found as an exterior sealing solution, EPDM has WRAS approval and provides strong resistance to environmental conditions over its lifespan.

Resistant to weather and abrasion, Neoprene rubber gaskets are also used where mild chemicals or oils are processed.

The blend of isobutylene and isoprene forms an impermeable seal that is often used in processing gases. It also has excellent thermal and anti-ageing properties.

Hypalon is almost completely ozone and UV resistant with excellent recovery and stability properties when used in harsh environmental conditions.

Silicone Rubber Gaskets have heat tolerance up to 220°C are often used in food production and has FDA approval.

This flouroelastomer compound is resistant to most petrochemicals, hydrocarbons and solvents. It’s commonly used in manufacturing, automotive and petrochemical applications.

Nitrile rubber gaskets are a versatile and reliable sealing solution for a variety of applications. They are resistant to a wide range of fluids, abrasion, and temperature extremes.

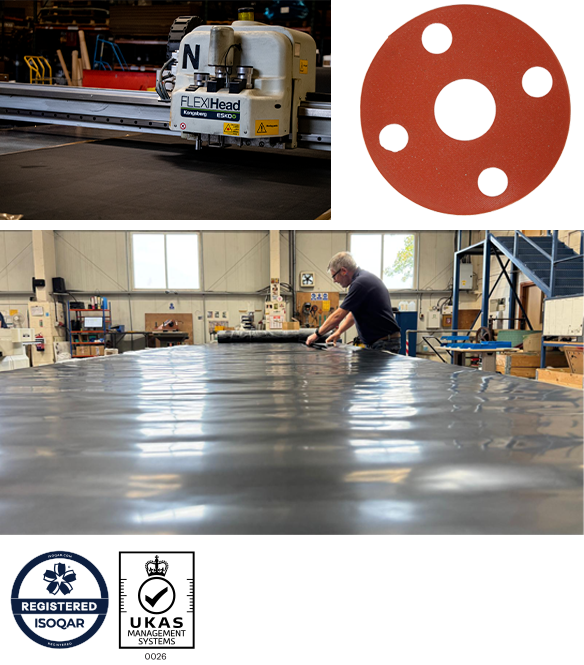

All Dobsons Gaskets products are precision cut in-house using advanced conversion machinery, ensuring every gasket meets exact specifications. By combining state-of-the-art production techniques with decades of experience, we are able to efficiently handle both high-volume orders and bespoke, small-batch requirements, delivering consistent quality and accuracy across every project.

Our process begins with careful material selection, ensuring the chosen rubber or silicone meets the specific performance, temperature, and chemical resistance requirements of each application. Using CAD design and engineering expertise, we develop detailed technical drawings and prototypes, enabling clients to visualise and refine their gasket designs before production.

We offer a full turnkey service, guiding clients through every stage, from materials specification and design, through precision manufacture, to secure worldwide distribution. For clients who already have designs or templates, we can produce single units or large production runs, maintaining the same high standards of quality and consistency.

Every gasket we supply complies with recognised national and international standards, giving clients confidence that their components meet industry benchmarks for safety, reliability, and performance.

The properties of common sheet rubber polymers optimise performance of the materials under specific circumstances of heat, moisture and pressure. Below we have listed some common rubber and rubber polymers as guidance to their characteristics in operation. Please contact us for more information about the specific gasket materials for your application.

| Materials | Temperature Range | Max PSI/BAR | PN Range | Download |

| Butyl | min - 40 max 120 °C | 10 bar | 2.5/320 | |

| EPDM | min - 40 max 120 °C | 10 bar | 2.5/320 | |

| Natural (Pure Gum) | min -25 max 70 °C | 10 bar | 2.5/320 | |

| Neoprene | min -30 max 120 °C | 10 bar | 2.5/320 | |

| Neoprene - Cloth Inserted | min -30 max 120 °C | 10 bar | 2.5/320 | |

| Nitrile (NBR, Buna-N) | min -30 max 120 °C | 10 bar | 2.5/320 | |

| SBR (Red Rubber) | min -20 max 70 °C | 10 bar | 2.5/320 | |

| SBR - Cloth Inserted | min -20 max 70 °C | 10 bar | 2.5/320 | |

| Silicone | min -90 max 225 °C | 10 bar | 2.5/320 | |

| Viton | min -20 max 275 °C | 10 bar | 2.5/320 | |

| Boiler Seal | min -25 max 120 °C | Up to 12 bar | 2.5/320 | Boiler Seal datasheet |

| Prekev Rubberised Cloth | min -250 max 300 °C | 35 bar | 2.5/320 | Prekev Rubberised Cloth datasheet |

Our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide range of gasket applications.

Rubber gaskets are widely found in a multitude of everyday industrial and domestic applications Most common uses for these gaskets include sealing substrates against leakage, environmental factors, vibration, temperature and pressure. Different rubber polymer material sheets are used to manufacture gaskets that remain stable under extreme cold or extreme heat, or withstand corrosive chemicals without losing integrity and flexibility. Talk to us about the best material for your application.

We supply a vast range of gasket materials, available to buy directly or order from us. For more information visit the Gasket Sheet Materials page