Metal gaskets is a term often used to describe any size of gasket, shim or washer that is manufactured from elemental metals or alloys such as steel, brass or titanium. Specialist metal alloys such as Inconel, which is composed of nickel, chromium and iron, have properties suited to processes that undergo extreme pressures or temperatures.

We precision engineer a wide range metal gasket for commonplace and critical applications.

Heat exchanger gaskets and small spinner gaskets can be fabricated in simple rings or more complicated crossbar designs and configurations.

Composed of a grooved metal core and a graphite or composite sealing layer, camprofile gaskets are supplied in standard and nonstandard dimensions.

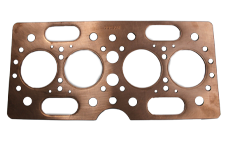

We have a wealth of experience re-templating and manufacturing classic car gaskets from drawings or the physical component. .

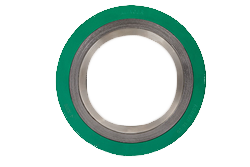

Comprising preformed rings of chevron shaped layers of metal and filler material, spiral wound gaskets are often used in higher pressure applications. Find out more.

Metal shims and support washers are commonly used to fill spaces or take up play in mechanical applications. We produce standard and bespoke shims.

Standard and bespoke ring joint gaskets are precision manufactured to national and international standards using materials such as carbon and stainless steel.

Metal O Rings are used in high temperature and pressure mechanical applications. The combination of metal tubing and high-temperature alloys offers good ‘springback’ properties.

Often used as a seal for steam and hot valves, taylor ring gaskets are cut from a variety of sheet metals and formed into corrugated concentric rings.

We manufacture a comprehensive standard range of metal and metal-jacketed gaskets or can precision form components based on custom dimensions. Metal gaskets have applications across a multitude of mechanical and production processes

Clients utilise our full turnkey gasket manufacturing service for help with materials specification, along with CAD gasket design, prototyping, manufacture and worldwide distribution. All gaskets are supplied to recognised national and international standards

We precision cut gaskets from metal and alloy sheet materials to any thickness, shape or size. The primary characteristics of the winding and filler materials are defined below. We’re also happy assist in specifying the best combination of materials.

| Materials | Temperature Range | Max PSI/BAR | PN Range | Download |

| Copper | min -250 max 400 °C | 600 | 2.5/320 | Copper datasheet |

| Brass | max 800 °C | 500 | 2.5/320 | Brass datasheet |

| Titanium | min -250 max 350 °C | 1000 | 2.5/320 | |

| Soft Iron, Low Carbon Steel | min -60 max 500 °C | 1000 | 2.5/320 | |

| Stainless Steel,Type 304 | min -250 max 550 °C | 1000 | 2.5/320 | |

| Stainless Steel, Type 316 | min -100 max 550 °C | 1000 | 2.5/320 | |

| Stainless Steel,Type 321 | min - 250 max 550 °C | 1600 | 2.5/320 | |

| Stainless Steel,Type 347 | min - 250 max 550 °C | 1600 | 2.5/320 | |

| Stainless Steel,Type 410 | max 450 °C | 1200 | 2.5/320 | |

| Stainless Steel,Type 430 | max 450 °C | 1400 | 2.5/320 | |

| Nickel | min - 250 max 600 °C | 1400 | 2.5/320 | |

| Monel | min-125 max 600 °C | 1500 | 2.5/320 | |

| Inconel | min-100 max 950 °C | 2000 | 2.5/320 | Inconel datasheet |

| Hastelloy | min -200 max 450 °C | 2000 | 2.5/320 |

Our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide range of gasket applications.

Metal gaskets are most often fabricated for use in applications where extreme temperatures, pressures and chemicals are present. In the case of metal shims and washers, they are used in commonplace electrical and mechanical equipment, such as engines, machinery and home appliances.

We supply a vast range of gasket materials, available to buy directly or order from us. For more information visit the Gasket Sheet Materials page