Shims are precision-engineered components used to fill gaps, provide alignment, and ensure proper spacing between two surfaces. They are crucial in maintaining the integrity and functionality of mechanical assemblies by compensating for manufacturing tolerances, thermal expansion, and wear over time.

Shims are typically flat, thin pieces of material that can be inserted between parts to achieve the desired fit or clearance. They come in various types and materials, tailored to specific applications and environments. Choice of material is dictated by application, and our expert technicians are available to advise on the best configuration based on an application’s requirements. The primary functions of shims include:

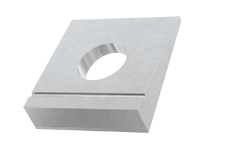

Thin pieces of material used to fill in small spaces or gaps. Typically a solid piece of metal, traditional shims are designed into the assembly as pre-planned parts. They are not adjustable, and are designed with specific thicknesses, lengths, widths, etc.to suit the application they are made for.

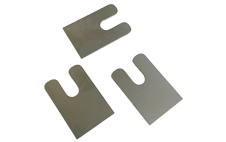

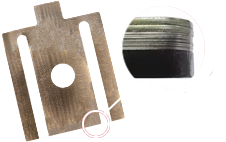

Laminated shims, also called surface-bonded laminated shims, consist of a stack of peelable metal layers built up from layers of precision-gauge metal foil. Each layer is bonded to one above and below it over their entire surfaces. Engineers can peel off enough layers to adjust the thickness of the shim as required.

Unlike surface-bonded laminated shims, the layers of edge-bonded shims are only bonded to layers above and below them at the edges of that layer’s profile. This makes it much easier to separate layers in the field. Because these shim sets are easy to peel, layers that are not needed can be saved for use in a later application.

A tapered shim is a precision-engineered component characterised by its gradually changing thickness across its length or width. Unlike standard shims, which maintain a uniform thickness, tapered shims are designed to accommodate variations in gap sizes, ensuring a more precise fit and alignment in mechanical assemblies.

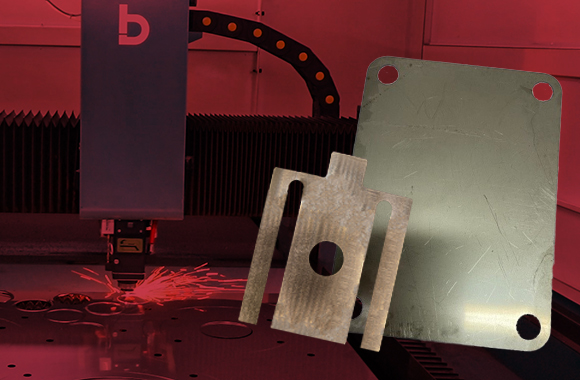

The manufacturing of shims requires high-precision engineering due to the incredibly fine thicknesses applications often require. Our expert team of engineers utilise CAD machining processes to plan a specific set of custom shims before our cutting edge technologies fabricate them. The various manufacturing methods include:

CNC Press Offers high-speed, high-volume precision cutting from a stamp. Used to manufacture traditional type shims, mainly from plastic materials

Laser Cutter We use a 2kW Fibre Laser cutter to cleanly cut complex metal shims with the highest precision

WaterJet Machine For high-volume, precision cutting of any shim type from most materials, our WaterJet cutting technology is at the top of the game

Our highly experienced team of expert engineers will be able to discuss your application and design and fabricate the right shim set for your needs. Below is a simplified reference guide to the various materials typically used in shim manufacturing.

| Material | Temperature Range (°C) | Chemical Resistance | Typical Application |

| Copper | -200°C to 260°C | Good | Electrical systems, plumbing, and low-pressure applications |

| Aluminium | -100°C to 300°C | Good | Low-pressure seals, HVAC systems, aerospace |

| Brass | -100°C to 260°C | Fair | Water systems, plumbing, and low-pressure gas sealing |

| Stainless Steel | -200°C to 815°C | Excellent | High-temperature, high-pressure systems; chemical plants |

| Titanium | -250°C to 600°C | Excellent | Extreme environments, chemical processing, marine |

| Carbon Steel | -250°C to 600°C | Poor | Low-cost general applications, oil and gas industry |

| Nickel | -200°C to 760°C | Excellent | High-temperature, chemical, and nuclear industries |

| Zinc | -100°C to 150°C | Fair | Galvanized steel gaskets, HVAC, low-pressure systems |

| Material | Temperature Range (°C) | Chemical Resistance | Typical Application |

| Nitrile Rubber | -30°C to 120°C | Good | Oil and fuel systems, automotive, general industrial |

| Neoprene Rubber | -40°C to 120°C | Good | Refrigeration, HVAC, chemical resistance applications |

| EPDM Rubber | -50°C to 150°C | Excellent | Water systems, weather sealing, and chemical plants |

| Viton Rubber | -30°C to 200°C | Excellent | High-temperature, chemical, fuel systems, aerospace |

| Silicone Rubber | -60°C to 230°C | Fair | High-temperature seals, medical, food processing |

| PTFE (Teflon) | -200°C to 260°C | Excellent | Chemical and high-temperature applications |

| Nylon | -40°C to 120°C | Good | Industrial machinery, automotive, oil and gas, electrical seals |

| PVC | -15°C to 60°C | Good | Water seals, chemical processing, drainage systems |

Our highly experienced technicians can advise you on the best shim type and material for your specific application.