As environmental regulations tighten, industries across the UK are under increasing pressure to reduce emissions and operate more sustainably. While much of the focus is placed on large-scale systems and technologies, small components like gaskets play a critical role in ensuring compliance.

In the UK, emission control requirements are shaped by a combination of domestic laws and international agreements. Industries must adhere to:

- Industrial Emissions Directive (IED): Setting limits on emissions to air, water, and land from industrial installations.

- Environmental Permitting Regulations (EPR): Requiring operators to demonstrate that their equipment is designed and maintained to minimise environmental impact.

- Clean Air Strategy and Net Zero Targets: Encouraging businesses to cut fugitive emissions, unplanned leaks of gases or vapours, from equipment such as flanges, valves, and pipework.

For petrochemical, automotive, and manufacturing facilities, the choice of sealing solutions has a direct impact on emissions performance and what are known as fugitive emissions.

What are Fugitive Emissions?

Fugitive emissions are unintentional leaks of gases or vapours that escape from pressurised equipment, such as valves, pumps, flanges or gaskets, rather than being released through a controlled venting system. These emissions often consist of volatile organic compounds (VOCs) or other hazardous substances that can contribute to air pollution, safety risks and regulatory compliance issues. As gaskets play a vital role in sealing joints and preventing leaks, selecting the correct gasket material and ensuring proper installation are essential steps in minimising fugitive emissions.

Advanced Gasket Materials: Reducing Fugitive Emissions

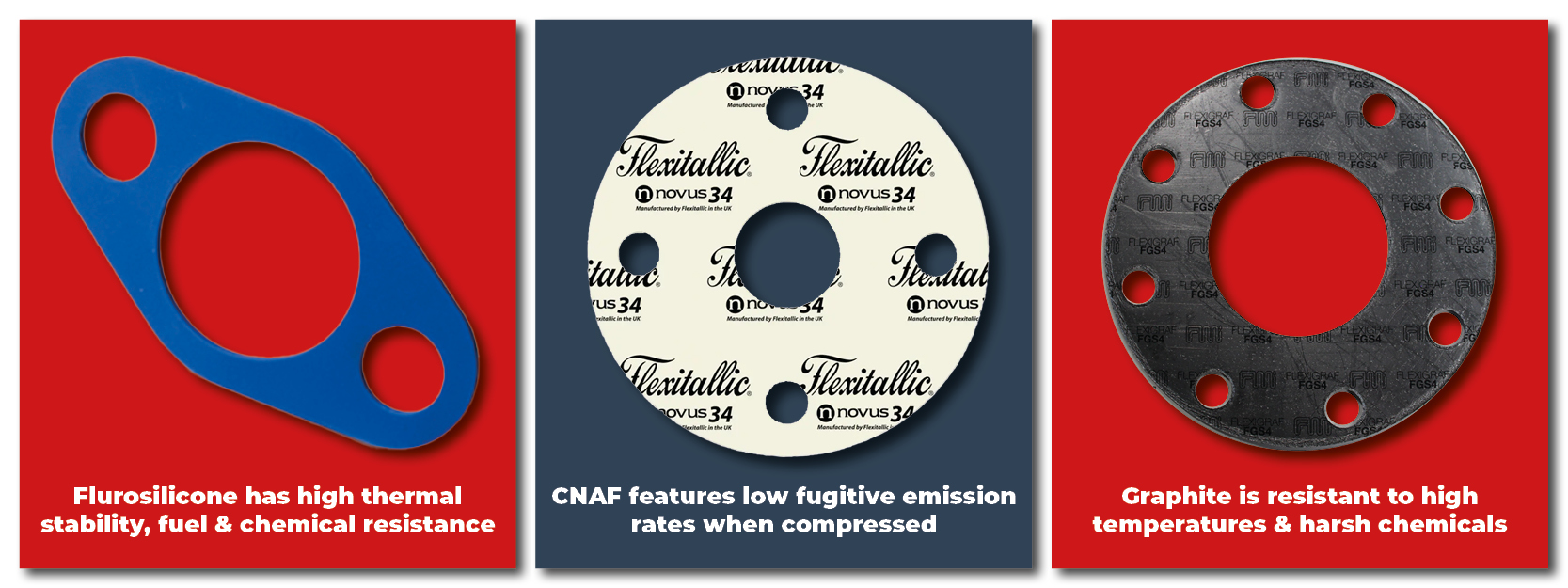

Examples of advanced materials used in reducing fugitive emissions.

Fugitive emissions often originate from flange connections, manways, and other critical sealing points. A poorly fitted or degraded gasket can allow harmful gases or volatile organic compounds (VOCs) to escape, leading to environmental harm, operational risk and reputational damage.

Correct material selection, alongside good installation practices, is vital for preventing leaks. With advancements in material science, modern gaskets can offer higher performance and reduced emissions. Some of these innovative sealing materials include:

- Graphite gaskets: Resistant to high temperatures and aggressive chemicals, ideal for critical flange sealing.

- Flurosilicone blends: Adds enhanced fuel and chemical resistance to high thermal stability.

- Low-emission sheet materials: Compressed Non-Asbestos Fibre (CNAF) reduces leakage rates to near-zero levels.

Gaskets designed for emission control are vital in sectors where safety, compliance, and efficiency are non-negotiable. Petrochemical plants, automotive exhaust systems and industrial manufacturing processes depend on advanced sealing solutions to prevent fugitive emissions.

Partner with Dobson Gaskets

As the UK moves toward ambitious emissions reduction goals, the role of reliable sealing technology cannot be overstated. With decades of experience and a commitment to innovation, Dobson Gaskets’ precision manufacturing helps businesses across industries achieve compliance and protect their bottom line.

NEED RELIABLE AND COMPLIANT SEALING FOR EMISSION CONTROL?

Talk to Our Experienced Technical Team

Contact our team today to learn how we can support your emission control strategy with bespoke gasket solutions.