In gasket design, surface finish is one of the most critical yet often misunderstood factors affecting seal performance. The interaction between the gasket material and the flange surface determines not only how effectively the gasket seals but also how long it maintains that seal under pressure, temperature, and chemical exposure.

Surface texture, defined by measurable roughness parameters, plays a decisive role in ensuring the right balance between sealing integrity and gasket longevity.

The relationship between flange finish, gasket material, and bolting force is a delicate one. A well-prepared surface does not need to be mirror-smooth, but it must be consistent and within the recommended roughness range for the chosen gasket type. Too rough a finish increases the risk of leakage, while a surface that is too smooth can lead to gasket creep and blow-out.

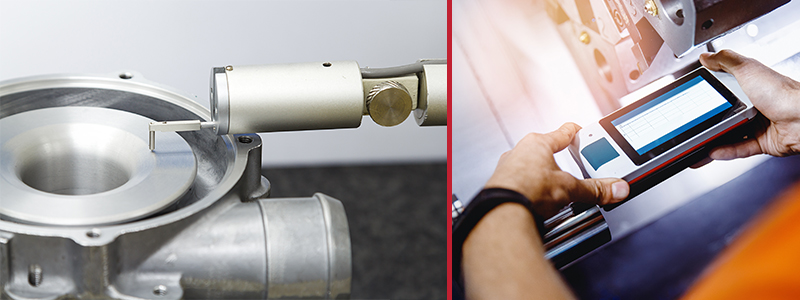

In critical applications, such as pressure vessels, heat exchangers, and pipelines, measuring both Roughness Average (Ra) and maximum roughness height (Rz) provides a more complete understanding of the sealing surface. Using both parameters together enables engineers to predict performance more accurately and select gasket materials that deliver consistent, long-term sealing integrity.

Ra vs Rz: Understanding the Difference

Ra is the most widely used surface roughness measurement. It represents the average deviation of the surface profile from the mean line over a measured length. Because it averages all peaks and valleys, Ra provides a generalised figure that smooths out extremes. This makes it a useful baseline, but sometimes insufficient for predicting sealing performance where surface irregularities are significant.

Measuring and recording the maximum roughness height (Rz) of a flange surface.

Rz, on the other hand, measures the average height difference between the five highest peaks and five deepest valleys within a sampling length. Unlike Ra, Rz captures the extremes of the surface profile and provides a more detailed view of its texture. A flange surface with the same Ra value could have very different Rz values, one relatively even, another marked by deep scratches or pronounced machining marks.

For this reason, Rz is often a more reliable indicator when evaluating gasket performance, especially in situations where surface irregularities can compromise sealing integrity. While Ra remains useful for general machining control, Rz offers better insight into how the gasket will interact with the actual surface topography.

When Rz Measurement Takes Priority

In applications where the flange surfaces are subject to wear, corrosion, or inconsistent machining, Rz provides a truer picture of the sealing surface. This makes it particularly valuable in maintenance and repair operations, where flanges may have been re-machined or resurfaced multiple times, resulting in uneven profiles.

For instance, in high-pressure or high-temperature applications where gasket materials such as graphite or spiral wound gaskets are used, deep surface valleys (reflected by a high Rz) can create leakage paths if not properly compensated for. Measuring Rz ensures that these peaks and valleys are within acceptable limits before installation.

Similarly, for softer gasket materials that rely on surface conformity, such as compressed fibre, PTFE, or elastomeric gaskets, Rz helps to ensure that the surface roughness does not exceed the material’s ability to deform and fill imperfections. In such cases, relying solely on Ra could lead to an overestimation of sealing capability.

Choosing the Right Gasket Material for Rough or Irregular Finishes

When sealing flanges that exhibit rough or damaged surfaces, the choice of gasket material becomes especially important. Softer and more compressible materials generally perform better, as they can adapt to surface irregularities and maintain contact pressure across the sealing face.

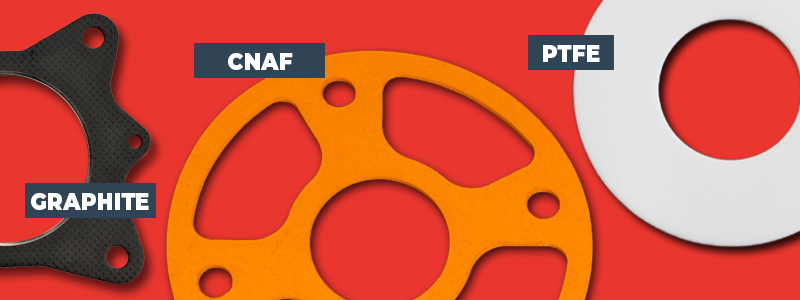

Graphite gaskets, particularly reinforced grades, are commonly preferred for moderately rough finishes because of their resilience and ability to conform to flange topography under bolt load. They also perform well under high temperatures and chemical exposure.

For extremely uneven or pitted surfaces, expanded PTFE (ePTFE) gaskets are highly effective. Their soft, pliable nature allows them to fill even deep imperfections without excessive bolt loading. In less demanding applications, compressed non-asbestos fibre (CNAF) gaskets also offer good adaptability to surface roughness, provided operating temperatures and pressures remain within the material’s limits.

Gasket Material Suitability by Surface Roughness

| Gasket Material | Recommended Ra/Rz | Key Material Properties |

|---|---|---|

| Spiral Wound (Graphite or PTFE Filler) | Ra: 3.2-6.3 µm Rz: 15-40 µm |

Combines metal strength with filler compressibility; handles moderate irregularities; suitable for high-pressure, high-temperature applications. |

| Reinforced Graphite | Ra: 1.6-6.3 µm Rz: 10-40 µm |

Excellent conformability and resilience; resists chemical attack and thermal cycling; good for moderately rough or aged flanges. |

| Expanded PTFE (ePTFE) | Ra: <= 12.5 µm Rz: <= 60 µm |

Extremely soft and pliable; fills deep surface imperfections; ideal for damaged or pitted flanges and low bolt load conditions. |

| Compressed Non-Asbestos Fibre (CNAF) | Ra: 3.2-6.3 µm Rz: 15-40 µm |

Good adaptability and recovery; suitable for general industrial use where surfaces are slightly uneven. |

| Rubber / Elastomeric (Nitrile, EPDM, Viton) |

Ra: <= 12.5 µm Rz: <= 60 µm |

High flexibility and compression; excellent for rough or irregular surfaces in low-pressure applications. |

Partner with Dobson Gaskets

When flange refurbishment is not an option, and roughness is unavoidable, the gasket’s compressibility and recovery properties become the deciding factors. Selecting materials engineered for high conformability ensures a reliable seal even on imperfect surfaces.

At Dobson Gaskets, we design and manufacture precision-engineered gaskets and seals perfectly suited to the surface condition, ensuring gasket reliability and long-term performance.

NEED EFFECTIVE SEALING FOR IRREGULAR OR ROUGH SURFACES?

Talk to Our Experienced Technical Team

Contact our team today to learn how we can design and fabricate reliable and long-lasting flange seals.